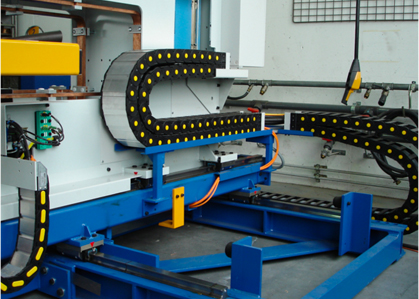

Nylon Cable Chains

A wide range of Brevetti Stendalto nylon cable chains designed to support cables and hoses connected to automated equipment.We supply a wide range of Brevetti Stendalto nylon cable chains designed to support cables and hoses connected to automated equipment. Also known as energy chains, drag chains, cable carriers or cat-track, the chains enable movement of the cable while providing superior protection, reducing stress on the cables and preventing cable entanglement.

Automation made easy

Our chains are suitable for light, medium and heavy loads and can withstand any heavy-duty application put to the test. Whether you need an energy chain that allows for horizontal, vertical or circular movement, sliding for long travel distances beyond 400m, whatever your intended use – we have a chain for it.

Brevetti Stendalto nylon cable chains are so versatile you’ll see them applied across various industries that require packaging and automated handling, storage and transportation and robotics. We also specialise in supplying nylon cable chains for manufacturing, mining, offshore drilling, ports, oil and gas and event staging technology.

The original creators of nylon cable chains

As the inventors of nylon cable chains, Brevetti Stendalto remains at the forefront of cable chain technology. To ensure the highest standards in products on the market, Brevetti Stendalto invest heavily in R&D. They continuously adopt the latest technology to solve today’s challenges in cable and hose protection in the most innovative way.

Nylon cable chain products

With unmatched durability and lifespan, our range of nylon cable chains are designed to make your operations more efficient and productive, while reducing maintenance costs and downtime.

Nylon energy chain series features

- Large surface allows the chain to slide on itself

- Cross pieces open and close with a “snap-fit” action

- Nylon separator allows for cables to be laid apart from each other

- Smooth inner surface

- Steel or nylon end brackets with tiewrap clamp available

- Single connecting pivot pin offers high integrity in high performance applications (applies to medium series chains)

Chain Series Types

- Light & Medium Series

- Heavy cable chain series

- Sliding cable chain series

- Protection Series

- Robot cable chain series

- Large surface allows the chain to slide on itself

- Cross pieces open and close with a “snap-fit” action

- Nylon separator allows for cables to be laid apart from each other

- Smooth inner surface

- Steel or nylon end brackets with tiewrap clamp available

- Single connecting pivot pin offers high integrity in high performance applications (applies to medium series chains)

Our line of heavy nylon cable chains are ideal for use in high stress and high wear automation applications. Constructed with heavy sidebands, they provide superior protection, while ensuring maximum movement.

The heavy series also come with triple connecting pivot pins. The cross pieces are available in a variety of formats including:

- Cross pieces that open and close with a snap-fit action

- Aluminium rods

- Other materials available on request

Sliding nylon cable chains are used primarily on long travel distances (up to 900m) and are a great alternative to traditional conductor bars, festoon systems or cable/ hose reels. You’ll benefit from:

- Combined transportation of hydraulic cables/ hoses

- Use in critical environments prone to humidity, textile dust, negative

- Chemical and atmospheric components

- High velocities and values of acceleration

- Notably shorter installation times

- Reduction in the time taken for maintenance

A special feature in the sliding series is the integrated sliding skid, which allows the chains to slide on itself, reducing the friction due to the special polymers used.

The dimensions of the skid allow the chain to keep itself stable in applications with high velocities.

These chains have been tested using torsion and wear and tear, passing the tensile yield stress with exceptional results above high normal values (e.g. 318 21000 N).

- Completely enclosed designed to protect cables and hoses

- Large surface allows the chain to slide on itself

- Cross pieces open and close with a “snap-fit” action

- Nylon separator allows for cables to be laid apart from each other

- Smooth inner surface

- Steel or nylon end brackets with tiewrap clamp available

- Single connecting pivot pin offers high integrity in high performance applications (applies to medium series chains)

Any challenges you have with circular motion are easily resolved with nylon cable chains from our exclusive Robot series.

Specifically designed for rotary motion, the chain links are robust and stable so they can deliver outstanding performance even at high speed. Brevetti Stendalto robot chains are perfect for automated machines, welding and handling robots.

Features include:

- Quick removable covers for easy installation of the cables/ hoses

- Double pin – high strength in every condition

- Internal separations for the subdivisions of the cables/ hoses

- Inner surface without edges

- Special end brackets to ensure perfect fitting of the chain

- Support guide for correct functioning of the chain

The horizontal rotating chains can reach a maximum rotation of 540°. It’s also possible to use the chains in counter-rotation configuration by mounting them

on their side.

Start browsing our product range or get in touch and we’ll help you find the right nylon cable chain solution for your needs.